PLC and SCADA Training Courses

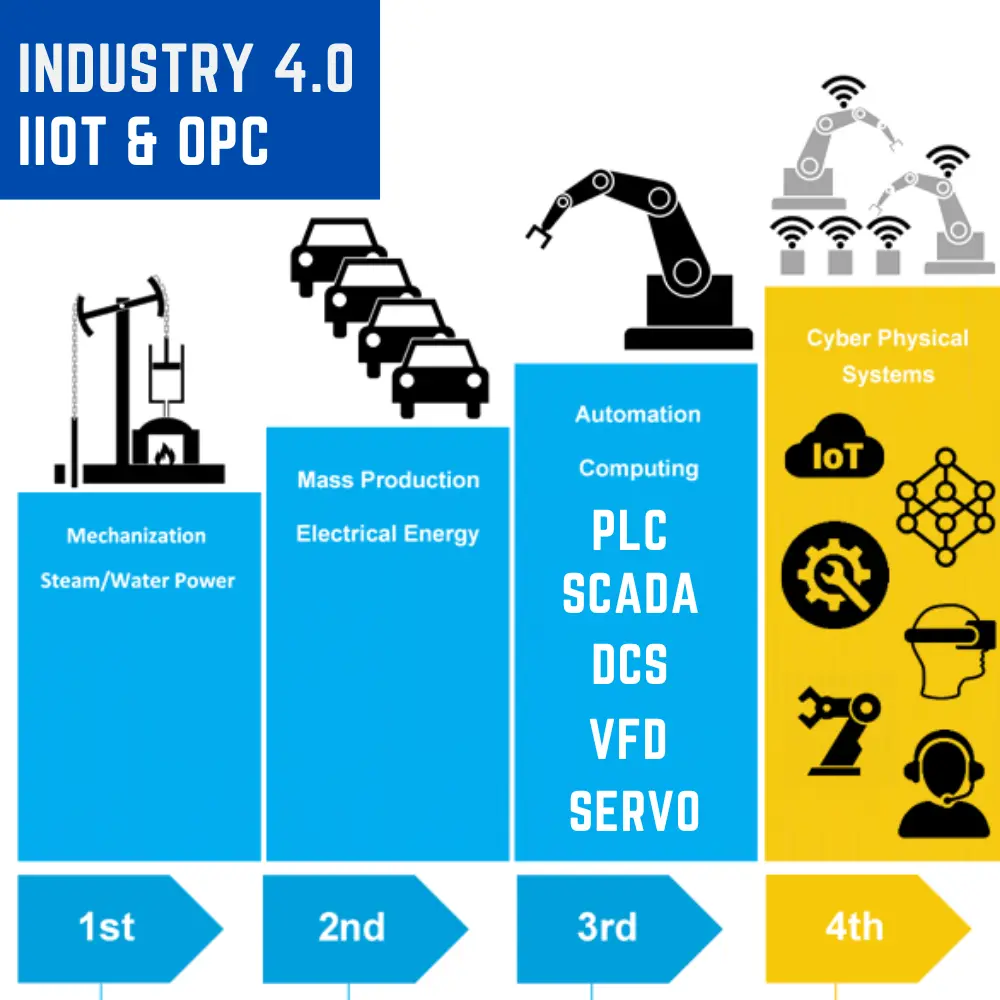

PLC And SCADA Training courses is designed to develop your understanding of PLC SCADA, DCS, VFD, HMI, SERVO, MCC Panel & Control Panel Designing and wiring, Testing, commissioning & Programming. You will learn to build an end-to-end Project application, IO Summary, estimation of project, BOQ, BOM, P&ID Drawings, Electrical Drawings, Installation, Field Devices and Controllers, Upload & Download Program, O&M manual Documentation, Checklist and much more. By the end of this course, you will have adequate awareness and confidence to pursue job roles as a Project Engineer.

Find Why We Are Unique ?

Course Overview

| PLC – Programmable Logic Controller | Allen Bradley, Siemens, Honeywell, ABB, Schnieder, Delta, Mitshubishi, Keyence, Omron, GE |

|---|---|

| SCADA – Supervisory Control & Data Acquisition | Wonderware Intouch, WinCC, I-Fix, Citect, KingVIEW, RS View 32, Factory Talk |

| Advance Siemens | TIA Portal, Profibus, Profinet, s7-317, Simatic Manager, Modbus, MPI |

| Field Instruments | Solonoid Valves, Control Valves, Actuator, Sensors, Transmitters Etc. |

| HMI – Human Machine Interface | Siemens, Delta, Schnieder |

| DCS – Distributed Control System | ABB, Siemens-PCS7 |

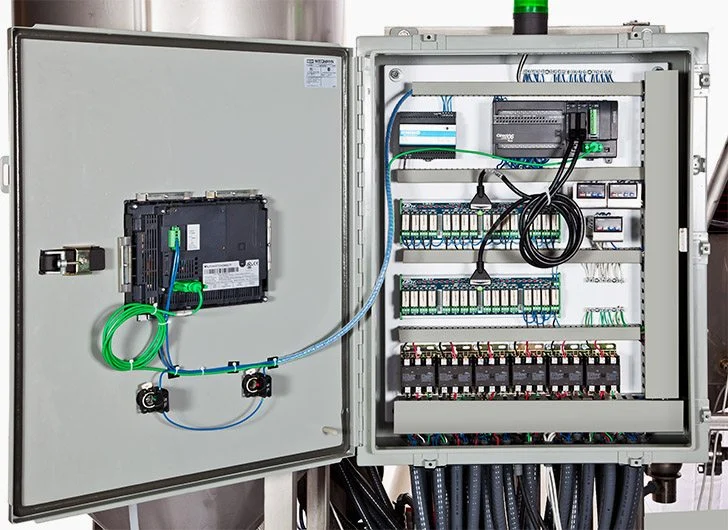

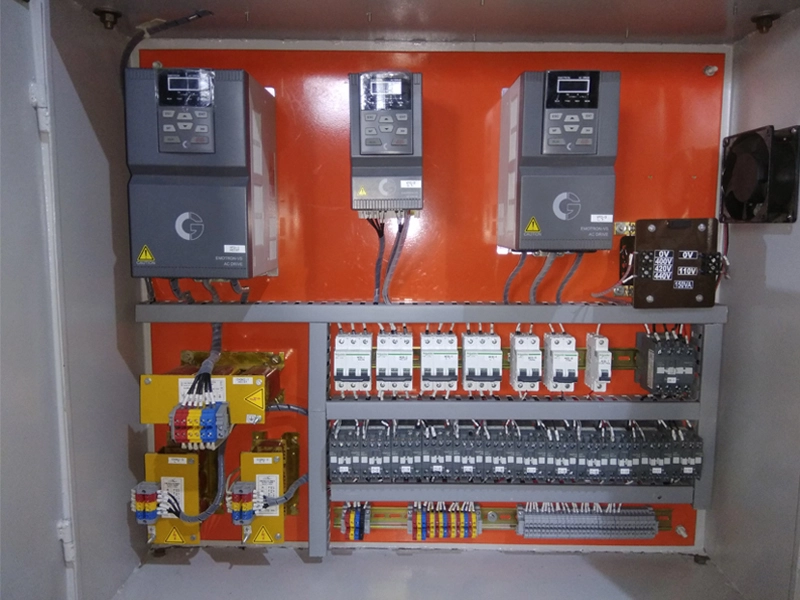

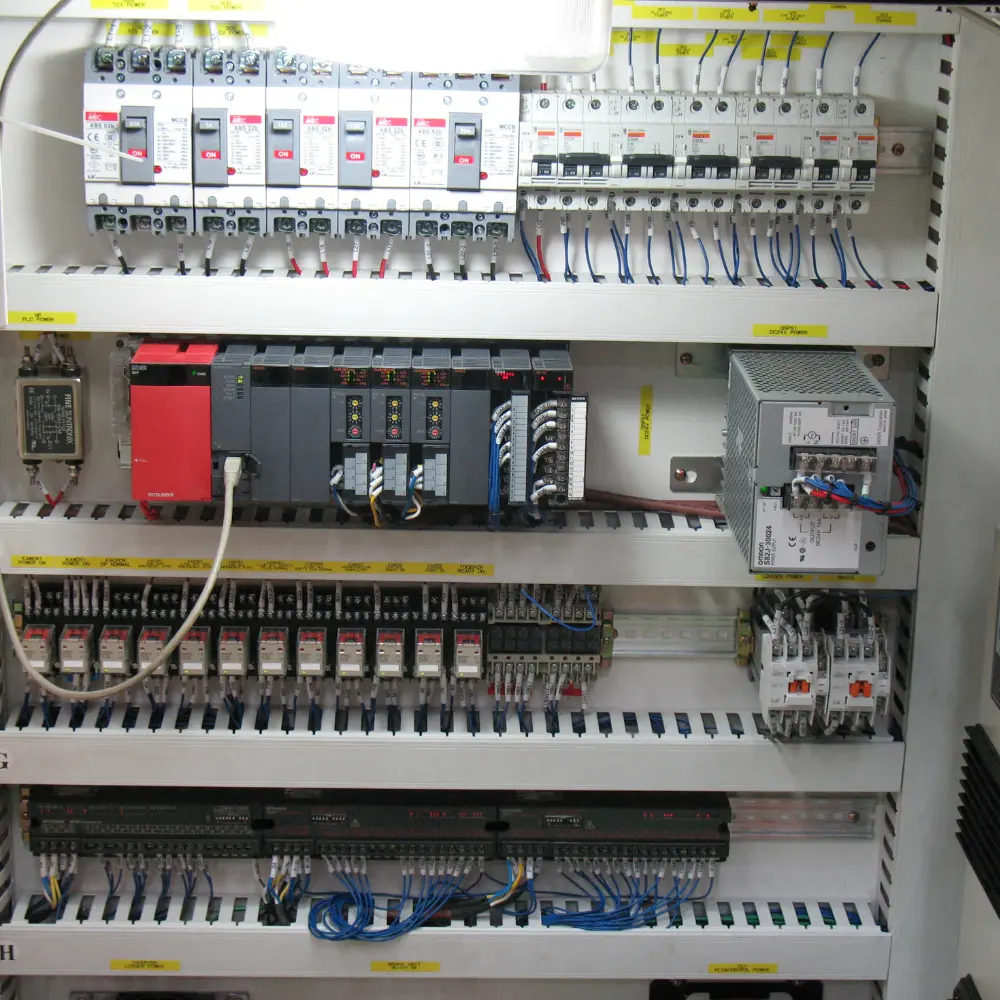

| CPD&W | Control Panel Design & Wiring, MCC Panel (DOL, Star-Delta), PLC Panel, Panel Draw. |

| Relay Logics | Relay logic Wiring & Design |

| Communication Protocol | Modbus [ ASCII, RTU, TCP IP ] , Ethernet IP, Profibus, Profinet, EtherCat, RS232, RJ45, RS485. |

| Servo Motors & Drives | Panasonic |

PLC SCADA Course Details

Panels & Hardwares

Placement Companies

- Introduction about industrial automation

- History of industrial automation, Need of automations in industries

- Example for industrial automation

- Automation control circuit and power circuit

- Field Instruments, Types and working of field devices

- Automation using relays and field devices

- Examples for relays and field devices & Logical functions done by relays and field devices

- Introduction about Programmable Logic Controller, History of PLC, Architecture of PLC

- CPU, IO Modules, Power Supply and Communications, Input and Output Devices, Need of PLC for Industrial Automation

- Types of PLC Models, Introduction about PLC Programming

- Types of Programming Languages, Introduction about PLC Programming software

- Ladder logic diagram, Structure of program, Procedure for creating ladder diagram, Logical function done by ladder program in software.

- Interfacing the field component to PLC, Sink and Source type wiring, Need of push button for industrial automation

- Importance of latching and unlatching concepts, Memory concept

- Working with – All Major Brands of PLC

- Interlocking & Trip concept

- Types of interlocking, Need of interlocking

- Timers, Types of timers & Example Problem for automation using timers

- Need for counters & Types of counters – Example for automation using counters

- Jump and subroutine & Importance of loop instruction – Examples : Automation using Jump and Subroutine. – Upload and Download Program.

- Introduction, definition and history of Supervisory Control and Data Acquisition,

- Typical SCADA System Architecture, Communication Requirements,

- SCADA systems in operation and control of interconnected power system, Power System Automation, Petroleum Refining Process, Water Purification System, Chemical Plant

- Remote Terminal Unit (RTU), RTU Configuration, RTU Hardware Modules

- Project Creation in Display, Tags, Library, Run Time, Security, Working with Properties, Animation, Alarm Setup, Trend, Language Switching, Interfacing PLC to SCADA.

- Industrial Project Documents

- P&ID Diagrams & IO List Preparation

- VFD Selection, Functions of VFD Switches & Symbols,

- Operate motor using VFD Console switches.

- Parameterisation, Checking Load, rated Voltage & current

- Comissionining, No Load Test, Speed Modulation, ON/ OFF Command, Trip Status, PID Tuning

- Interfacing PLC To VFD, Real Time Interface to PLC SCADA

- Intro to HMI

- Designining In HMI- Diffrent Types of Operaters, Textual & Graphical

- Properties for Design, I/O Configuration, Wiring of HMI, Data Handling

- Configuration & Interfacing from PLC to PC

- DCS – Distributed Control System

- Architecture of DCS, Hardware Configuration , I/O Modules, Communication Module, Troubleshooting

- I/O Wirining, Programming, CPU IP Setting & Addressing, Node Addressing, Upload & Download Monitoring,

- SCADA Interfacing, Fault Detection, Operater Interface, Designing, OPC / ODBC

- Communication Protocol, Ethernet

- Projects, Assignments & Test

PLC SCADA Training In India

Enhance your skills PLC SCADA Training In Bangalore expert with our comprehensive training courses. Sign up today for hands-on experience

Course Provider: Organization

Course Provider Name: Smart Integrators

Course Provider URL: www.smartintegrators.in

4.5