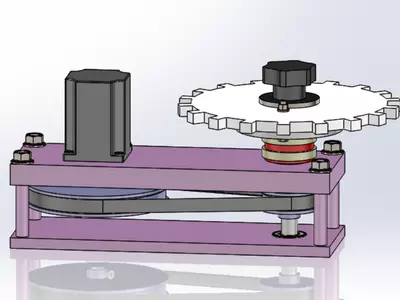

Warehouse Robotics AGV

Warehouse Robotics & AGV, also known as self-guided vehicles or driverless robots, are material handling systems or load carriers that navigate autonomously across a warehouse, distribution center, or manufacturing plant without the assistance of an onboard operator or driver.

In general, Autonomous Mobile Robots are widely used in distribution centers and fulfillment centres. We all have in mind those amazing videos with hundres of orange AMAZON Robots. AMRs replace traditional ecommerce fulfilment tools targeted at increasing pickers efficiency and productivity.They are used for order picking operations, zone picking, goods-to-person, autonomous piece picking or flexible sortation.

An AGV does exactly what the name says that it does. It is automatically guided. But what is it guided by? There are three main types of guidance systems used to ‘tell’ the robot where it needs to go.

- Wire guidance uses wires embedded in the plant floor that are sensed inductively by the vehicle in order to determine its lateral position.

- Inertial guidance uses gyroscopes and tracks the position of the wheel to find its position. Magnets are then placed in strategic locations to reset the system. This is key because it helps deal with the inevitable drift of the system.

- Laser guidance uses a laser emitter-receiver. It senses retroreflective landmarks strategically placed throughout the plant. By sensing the landmarks, the vehicle can then triangulate its position.

A mobile robot’s task is very similar to that of an AGV’s: get my stuff from point A to point B. However, the way it goes about it is completely different. Instead of using an infrastructure (wires, reflective markers, etc.), all of the sensing and path planning is done onboard by the robot. A mobile robot uses sensing components that are built onboard the machine in order to detect the environment. Commonly used sensors are area scanners, diffuse laser sensors, and cameras.

Typically, when a mobile robot is first installed, the robot is jogged around the plant while the sensors are running. After collecting all of the data from the plant floor, it then creates a virtual map of the entire plant floor. This is extremely useful because it gives the robot the ability to know where it is going without the use of a sensory infrastructure, while also allowing it to be taught a different map very easily. With an internal map and live sensor collection, the robot can navigate through an environment on its own, creating its own paths and sensing an ever changing plant floor.

Furthermore, the robot will use different algorithms to accomplish localization and navigation. These systems are usually referred to as SLAM algorithms: Simultaneous Localization And Mapping. The software can recognize key features in the environment to help localize itself. For example, if there is an oddly curved wall, the robot will use that feature to localize itself and ‘double check’ where it is on its map. This technique reduces the amount of drift in the system.

| AGV | Mobile Robot | |

|---|---|---|

| Navigation | Infrastructure: wire guidance, reflective markers, Radio Frequency ID, etc. | Trackless navigation. All sensing is done onboard. Senses the environment in a live fashion |

| Obstacles | Obstacles stop an AGV | Goes around obstacles and finds what the best path is according to its internal map |

| Flexibility | New tracks and infrastructure to be installed | Easily be remapped and taught new destinations and goals |

| Expandability | Possible to add new tracks and new units to it | Everything is managed on a fleet software package |

| Charging | Docking Station | Docking Station |

John M. –

I ordered on Friday evening and on Monday at 12:30 the package was with me. I have never encountered such a fast order processing.

Mark J. –

Everything is perfect. I would recommend!

admin –

This is a great product used by warehouse for dispatching and delivering packages