IIOT OPC Training

IIOT OPC Training course covers the evolution of data connectivity from proprietary data connectivity and custom protocol translation. The course also provides an overview of the OPC Specifications and common use cases for applications that implement them.

This IIOT OPC Training is delivered in a series of interactive interspersed sessions with practical exercises to demonstrate and reinforce the concepts presented.

Who Should Take the Course?

This course provides managers, process control engineers, and operators with a solid background around the basics of OPC the specifications, the applications, and their use cases. OPC technology is used in a wide variety of industries such as oil & gas extraction and refining, mining; pharmaceutical, food processing, discrete manufacturing, building automation, and more. Professionals working either directly or in support of the process control environment will benefit from this course.

IIOT OPC Training Objectives:

- The communication fundamentals related to OPC client and server-based architectures

- The principles of data connectivity to the end devices which are the building blocks of a modern industrial process control system

- The underlying technology behind OPC.

- Anyone with basic Programming skills interested in the OPC

- Designed for Both Students & Working Professional

- Fully Equipped Lab with Updated Software and Hardware facility

- Beginners intrested in Software Industry looking to kickstart their careers

- Industrial experienced faculties

Audience

- BE / Btech, ME / Mtech, Bsc, Msc, Phd,ITI, Diploma

- Working Professionals

Find Why We Are Unique ?

Course Overview

| Overview | Data Connectivity |

|---|---|

| OPC | OPC Classic, Data Access (OPC DA) |

| Server | OPC DA servers |

| Data Acquisition | Data Acquisition in OPC UA, OPC TUNNELLING, OPC BRIDGING |

| Data Sharing | Sharing Real-Time Data , Sharing Historical Data , Redundancy |

| Projects | Project development |

Course Feature

| Course Duration | 1 Month |

| Skill Level | Advance |

| Duration | 3 HRS ( Class+Lab) |

| Mode Of Training | Online | Offline |

| Projects | Real Time Projects |

| Certificate | Govt Affiliated, ISO, Global Certified |

Industry 4 & OPC Training Syllabus In Detail

- Data Connectivity Challenge Overview

- How to share data between multiple device and application vendors and make it available to applications that are used to visualize, analyze, and histories.control automation data.

- First Generation OPC: OPC Classic

- Based on the Microsoft Component Object Model (COM) and its distributed COM (DCOM) counterpart, the OPC Classic Specifications defined standardized mechanisms for data representation and sharing using a client/server architecture. This module deals with how OPC utilized the COM/DCOM infrastructure.

- The Microsoft Component Object Model (COM) , The roles of OPC client and server applications , The OPC server address space and browsing of The OPC server address space , Data format, including , Data Types , Attributes, OPC server discovery, OPC client/server connections

- The OPC Classic Specification for Data Access (OPC DA) – PRACTICAL

- The original OPC Classic specification. Applications based on the OPC DA specification deal with real-time data sources. PLCs, meters, switches are just a few examples of devices that generate real-time data best shared via OPC DA servers. This module examines the behavior of OPC DA servers and their basic

- Use cases for OPC DA servers , Connecting to a device , Reading data , Writing data , The use and significance of time stamps

- The OPC Classic Specification for Historical Data Access (OPC HDA) THEORY

- Applications that support the OPC HDA specification expose data stored or archived in a database, historian, or another data storage application. This module covers the use cases and specific functionality of these servers. Topics covered include:

- Use cases for OPC HDA servers , Connections to databases and historian applications , Raw history reads , Processed history reads , History writes

- The OPC Classic Specification for Alarms & Events (OPC A&E) THEORY

- Unlike the OPC DA and OPC HDA servers which work with real time and historical data respectively, OPC A&E servers provide a way to share Alarm and Event information in a standardized, vendor independent fashion. This data can come from OPC or non-OPC based sources since an OPC Classic A&E server uses event

- Use cases for the OPC A&E Servers – Event configuration – Event types – Event notifications – Subscriptions – Filters

- Security in OPC Classic THEORY

- By today’s standards, at the time the OPC Classic Specifications were developed, cyber security and cyber threats were in their infancy. Although cyber-attacks were not as prevalent as they are today, security did play a factor in the choice of Microsoft technology as the basis for the OPC Classic Specifications.

- Windows Security Framework including , Identities , Authentication , Authorization , Access Control Lists, Windows security updates , the OPC Security Specification

- Data Acquisition PRACTICAL

- The primary OPC Classic specification, called Data Access (DA), focused on data connectivity with real-time data sources to make it accessible to third party systems. Today, the OPC UA specification provides more sophisticated options for accessing different types of data using a variety of connectivity methods.

- Data Sources , Data Destinations , Data Acquisition in OPC Classic , Data Acquisition in OPC UA

- Data Management – PRACTICAL

- Once data is made accessible, a variety of OPC-based applications are used to work with the data. This may involve analyzing the data, storing it, and ensuring that it is distributed and delivered to the applications that need to consume it.

- Sharing Real-Time Data , Sharing Historical Data , Redundancy

- Troubleshooting PRACTICAL

- This module provides practical approaches and processes to follow when troubleshooting OPC communications, and identifies common factors that may cause complications. Participants are also introduced to the tools used to troubleshoot OPC infrastructure issues and the basics of how to use them

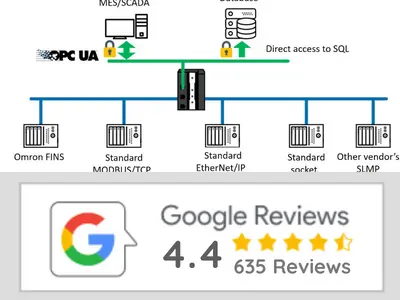

- DIFFERENT TYPES OF OPC’S BASED ON CILENT AND THE SERVER.

- The typical OPC connection scenario is a single server-client connection on a single computer as illustrated above, but there are more possibilities. For example, you might need to: OPC AGGREGATION: Connect an OPC client to several OPC servers.

- Reduce load on clients by making all of your data available through a single connection.

- Accessing data through a single client connection can also save you money if your client application required a license for each server connection.

- Bringing data from multiple sources together into one location allows you to easily bridge between different OPC Servers so that data from one server can be accessed in another server.

- Collect data from all of your OPC, DDE, ODBC, Web and TCP connected applications and present it to the user as a shared common data set.

- Writing custom applications is much easier when you can access data from multiple servers through a common interface, such as that offered by the OPC API. Client program never need to know which program originated the data in order to read and write to it.

- OPC TUNNELLING:

- Connect an OPC client to an OPC server over a network. This can be done with OPC tunnelling.

- More features of the OPC tunnelling product.SSL(SECURE SOCEKT LAYER) networking provides a secure connection over a network or Internet connection, including optional password protection.

- The tunnelling connection works across firewall boundaries. *The OPC provides immediate response and automatic recovery from network interruptions and link detection timeouts can be as fast as 50 milliseconds. Licensing is quick and easy using software key codes. No hardware keys to worry about

- A powerful built-in scripting language lets you fully customize your OPC applications by attaching custom code to process events and point changes.

- Full read and write support for Excel for accurate reporting and real-time Excel analysis of your plant data.

- The OPC also has the ability to aggregate data from multiple OPC Servers into a common data set, giving you a single point of access to all of your plant data. *Support for the latest web technologies lets you build powerful web applications for process visualization and control.

- Full read and write access to ODBC databases so you can log data to SQL/Access/Oracle, or integrate database information into your OPC applications.

- OPC BRIDGING:

- Connect an OPC server to another OPC server to share data. This is known as OPC bridging.

admin –

best Training offered In IIOT Programming, Hardware Intergration, IIOT Software And stack, Algorithm, OPC Server.